Changing Jewelry 3D Printing

Changing Jewelry 3D Printing

3D printing processing offers a myriad of benefits:

- Design costs decrease as designers enjoy enhanced freedom and flexibility, leading to intricate patterns. Automatic support addition further streamlines this process.

- Savings on development costs occur as plate-making and retouching expenses are eliminated. Printing outcomes perfectly align with designers’ styles, ensuring consistency.

- High-quality printing results are achieved, with wax models replicable, thereby reducing model management expenses.

- Printing operations can run 24/7, supported by the ability for one person to oversee multiple printers simultaneously, significantly cutting labor costs.

- Efficient utilization of printing filaments maintains stable pricing, promoting cost-effectiveness.

- Capacity expansion is simplified, requiring only the addition of more printers, which are space-efficient and easy to manage.

- Centralized model data administration reduces expenses associated with data protection, enhancing overall cost-efficiency.

Traditional processing presents several challenges:

- Design and training expenses rise as designers must manually create supporting structures for models, increasing complexity and time investment.

- Repetitive plate-making and retouching inflate development costs, impacting overall efficiency.

- Managing numerous rings of varying sizes becomes costly, as storage and organization demand significant resources.

- High reliance on skilled craftsmen and frequent turnover contribute to elevated labor expenses.

- Expansion necessitates larger operation sites, driving up self-production costs and logistical challenges.

- Outsourcing model data for printing escalates data protection expenses, posing security and financial concerns.

WaxJet 400 Specifications:

– Printing Method: MJP

– Printing Size: 289 * 218 * 150 mm (11.4 * 8.6 * 5.9 IN)

– Printing Mode: XHD:1200*1200*1600 dpi Layer:16 um

– Dimensional Accuracy: ±0.04 mm / 20 mm

– Working Environment: 18-28 ℃, 30-70 % humidity

Device Details:

– Device Size: 1352 * 775 * 1600 mm (53.2*30.5*63 IN)

– Net Weight: 480 kg (1058.4 LBS)

– Gross Weight: 630 kg (1389.2 LBS)

– Power Supply: AC 220-240 V, 50 Hz, 4 KW

Software and Connectivity:

– Slicing Software: WaxJetPrint

– File Input Format: .stl / .slc

– Email Notification: Supported

– Disk Capacity: 500G

– Network Connection: Network 10 / 100 / 1000 Ethernet / USB

– Supported OS: Windows 7 / Windows 10 (64 bit)

Material Specifications:

– Part Material: FFWJ1100 (N.W.: 3.0 kg/bottle)

– Supporting Material: FFMS3100 (N.W.: 3.6 kg/bottle)

– Automatic reloading: feature with 2 material bins for each device.

Wu Daozi Guanyin Statue

3D printing has reconstructed the original charm and

unprecedented innovation of national cultural relics

We’ve produced ten Wu Daozi Guanyin in mass for Xian Jue 3D and shorten time to market by 50%

Reduce manpower cost by 45%

Patent Number: 201830188448.1

Copyright Number: 2018-F-00024265

“Flashforge solution can reduce the dependency”

“Flashforge solution can reduce the dependency on manual repair model. Mass production for customization plays a key role in individualization”

Zhi Mei Tang CEO Yang Chunsheng

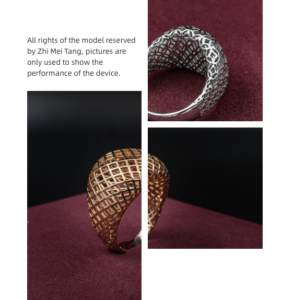

We’ve helped Zhi Met Tang Produce360 Hollow Structures at one time and shortened the time to market by 45%

Reduced labor costs by 20%