Flashforge WaxJet 510 & 400

Flashforge WaxJet 510 & 400

FLASHFORGE WaxJet 400HD & 510XHD Gourd Purple Pink Group

With over 15 years of expertise in 3D Jewelry Printing and a stellar 5-star customer service, Romanoff 3D specializes in delivering top-notch casting quality 3d Printers & Customer Support.

Utilizing Waxjet Support and 100% wax materials, the Flashforge WAXJET Printers like the Flashforge 510HD & Flashforge 400XHD ensure the production of flexible, durable, and high-quality jewelry patterns. These materials are meticulously designed to guarantee consistent results and reliable performance within existing lost-wax casting processes and equipment.

The Waxjet Support and 100% wax materials, melting like standard casting waxes, ensure defect-free castings with zero ash content, offering durability ideal for intricate features. Moreover, their high-contrast colors facilitate easy visualization of fine details.

With expanded print mode options, the Flashforge WAXJET Printers optimize quality for various design styles and types of jewelry, enhancing surface quality and ensuring accurate and repeatable fine jewelry production in nearly any metal through a lost wax casting workflow.

The Flashforge WAXJET Printers like the 400XHD boast high productivity, adapting to diverse manufacturing workflows with increased flexibility, efficiency, and quality in jewelry casting patterns production. With four printing modes catering to different speed, geometric complexity, and surface quality requirements, they facilitate high-volume production or rapid single-lane printing at fast print speeds, ultimately enhancing casting room efficiency. In addition to the 3 Print heads on the 400XHD will boost your productivity by 54% daily.

The advanced capabilities of software further optimize the file-to-pattern workflow, leveraging fast and versatile Flashforge WAXJET Printers print speeds along with batch support removal to deliver high-quality, ready-to-cast jewelry patterns.

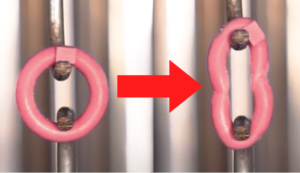

Moreover, the Flashforge WAXJET Printers enable high-resolution patterns with precise, razor-sharp edges and exceptionally crisp details, faithfully replicating the original CAD designs. Their superior resolution, coupled with dissolvable and meltable supports, ensures excellent surface quality, minimizing the need for extensive finishing labor and costly polishing of precious metals.

Moreover, the Flashforge WAXJET Printers enable high-resolution patterns with precise, razor-sharp edges and exceptionally crisp details, faithfully replicating the original CAD designs. Their superior resolution, coupled with dissolvable and meltable supports, ensures excellent surface quality, minimizing the need for extensive finishing labor and costly polishing of precious metals.

These printers offer maximum design freedom for high volume and mass customization jewelry manufacturing, with high throughput production of pure wax jewelry patterns for lost wax casting. Perfect for high-volume production of fine jewelry casting patterns, the Flashforge WAXJET Printers guarantee unique productivity, efficiency, quality, and design freedom.

Applications include pre-series and series production of jewelry metal pieces and customized jewelry metal pieces manufacturing. The benefits encompass expanded printing modes for optimized surface quality and productivity, faster pattern production to match metal casting workflows, high fidelity patterns with fine feature definition and sharp edges, greater geometric freedom with effective supports removal, high-performance durable casting wax, and a low Total Cost of Ownership (TCO).